Dr Claire McIlroy

Research Fellow 2017

Semi-crystalline materials in additive manufacturing

University of Nottingham

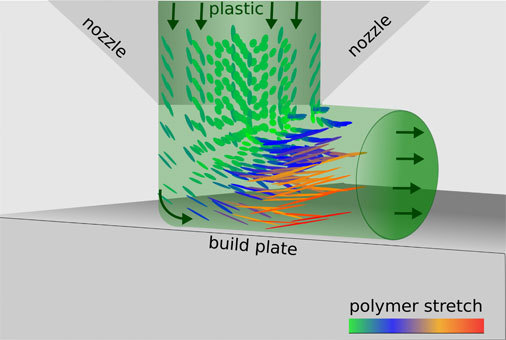

A fundamental understanding of the relationships between printing parameters, material rheology and mechanical properties is crucial for facilitating additive manufacturing production of structure-critical components and assemblies. This project addresses this gap in the current knowledge by providing molecularly-aware models to predict deformation and welding behaviour of semi-crystalline polymer melts.

Additive manufacturing, commonly known as 3D printing, has the potential to revolutionise manufacturing processes, offering increased precision, mass customisation and sustainability. Real-world issues present modelling challenges that must address material diversity, complex geometries, and non-uniform temperature profiles, as well as span multiple length scales. Claire’s expertise in fluid mechanics and molecular-scale physics of complex fluids are key to addressing these problems for current 3D printing applications. Although 3D printers can handle a diverse range of complex materials, studies quantifying how these materials behave under typical printing-flow conditions involving high flow rates, sophisticated shapes and rapid temperature changes are limited. The

main concern with the commonly-used, layer-by-layer extrusion

technique, known as fused-filament-fabrication (FFF), is the strength at

the welds between printed layers; bulk strength is never achieved in

these regions and the reason is currently unclear. Furthermore, FFF

continues to be unreliable, with common problems including under/over

extrusion, warping and bulging that are usually addressed via

`rules-of-thumb’ rather than physical understanding.

The main aim of this project is to develop new models that provide a description of the molecular structure of semi-crystalline polymers to understand their behaviour during FFF. Semi-crystalline materials have the important advantage of biodegradability, essential for regenerative medical applications. Whereas current models take a simplistic approach to the material properties (and neglect micro-structural effects), this new model will capture directional dependence of the molecular structure near interfaces, as well as crystallisation dynamics and their effect on welding and mechanical strength – relations which are yet to be addressed.

This research will develop a new framework to predict and control the final molecular structure of a semi-crystalline 3Dprinted part for a range of printing conditions. These findings will be a foundation for novel `real-time’ models that allow for modification to printing in response to the temperature profile, as well as the material properties, which can be difficult to predict due to the nature of commercial printing material. These real-time models that interact and feedback to the system concurrently with printing will overcome uncertainties, eliminate troubleshooting and allow for optimisation of speed, print quality and cost.